Our Journey Since 1950 – How Tradition and Innovation Go Hand in Hand

Tamsalu EPT AS is celebrating its 75th anniversary this year — three-quarters of a century of experience in Estonia’s metal industry. Our story began in 1950 as a Machine Land Reclamation Station, primarily organising forest drainage works and repairing the necessary machinery, mainly excavators and tractors.

Over the years, Tamsalu EPT has operated under various names, but the production activity has remained consistent. The company has undergone several development phases and now operates under the name Tamsalu EPT AS, making it one of Estonia’s oldest metal industry companies today.

Growth and Development Through the Decades

Although the early days were difficult, Tamsalu EPT grew steadily thanks to its managers’ selfless efforts and skilled leadership. In the 1950s, during the Soviet era, forest drainage operations were organised under Tamsalu MMJ, and the required machinery—excavators and tractors – was repaired on-site. It was the first enterprise in the entire Soviet Union focused on forest drainage.

In the early years, Tamsalu EPT was allocated approximately 12 hectares of farmland from Tõnusoo farm, where initially there were no buildings at all. Tamsalu was fortunate to be chosen as the location for a Machine Land Reclamation Station in 1950, which soon became a well-known and respected enterprise across Estonia.

Special credit goes to the station’s first director, Aleksei Potjomkin, who built a fully functioning company with proper infrastructure from scratch in just a few years, making Tamsalu MMJ one of the top-performing stations in the Soviet Union.

Potjomkin was known for his strict discipline — he did not tolerate idlers or drunkards and frequently visited forest drainage sites to maintain order when needed.

The first office was located on Tehnika Street, near the current Grossi store, in a house nicknamed “Paruni-Muti.” It consisted of two small rooms — a living room and kitchen — which accommodated 7–9 employees. By the end of the same year, construction began on the first barracks-style residential building.

1950s: Establishing the Production Base and Early Operations

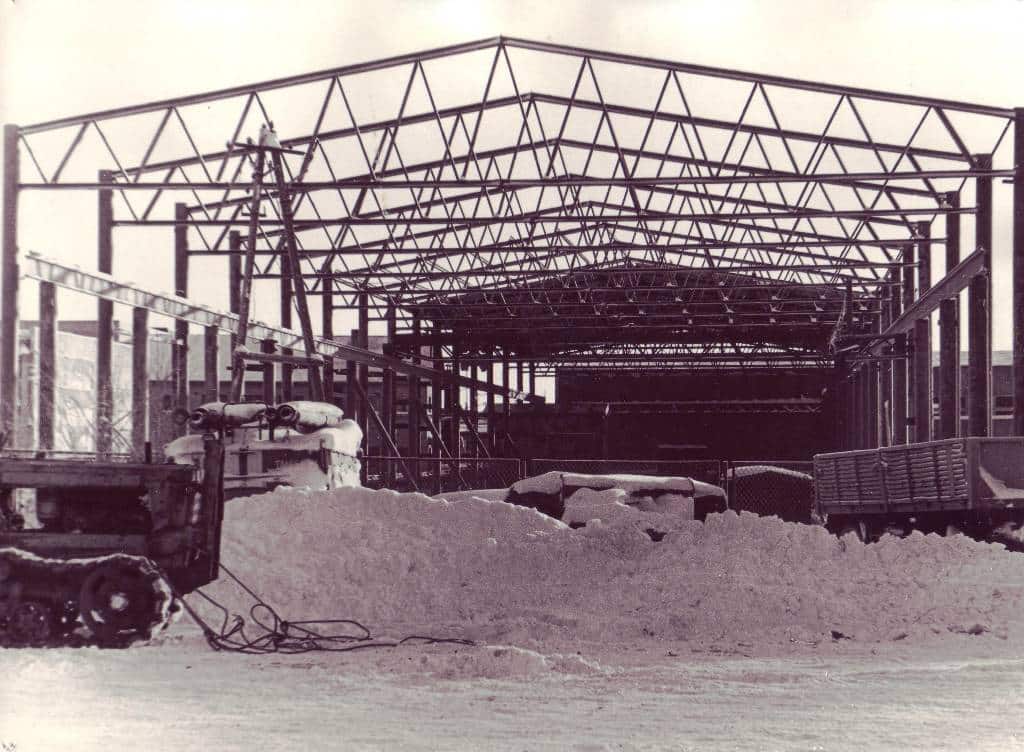

The 1950s were the founding years of the Tamsalu Machine-Forest Drainage Station. The site was built from scratch with no existing infrastructure or machinery. Initial efforts focused on constructing the first workshops, residential buildings, and office facilities, as well as deploying forest drainage machinery.

Working conditions were harsh, and shortages of construction materials and labor posed serious challenges. Nonetheless, a stable production and organizational structure emerged, laying the foundation for future growth. The workforce expanded, and the first cultural and sports events were held.

1960s: Technological Progress and Social Development

The 1960s brought significant expansion and technological advancement. Forest drainage reached a new level of quality, supported by modern machinery, facilities, and infrastructure. Financial support from Moscow and strong ties between Estonian forestry experts and Finland helped spread technical knowledge.

New residential and office buildings were constructed, an in-house construction crew was established, and a kindergarten was built, improving employee well-being. The company’s social and cultural life also thrived — sports events and competitions strengthened team spirit. Organizational restructuring improved workflow and boosted efficiency.

1970s: The Peak Period and Record Production Volumes

The 1970s marked the golden age of forest drainage at Tamsalu EPT. The workshop expanded, machinery was modernized, and output increased tenfold. The term “forest drainage” was replaced with “forest land improvement.” Projects were also carried out extensively in the Karelian ASSR, with many workers relocating from Estonia.

Employee living conditions improved, machine crews received cars and motorcycles, and operations became more efficient. New housing, dormitories, a swimming pool, and sports facilities were built. Several new traditions were introduced, such as Women’s Day celebrations and the Viru Games. The workshop received numerous awards and accolades.

Although record volumes were achieved, from 1975 onwards, greater attention was paid to work quality and project complexity. The workforce grew to nearly 100, and both equipment and production capacity saw significant upgrades. Workshops and public facilities were also expanded.

1980s: Growth and Entry Into Export Markets

The 1980s were a period of major growth. New buildings and technologies were introduced, the workforce increased, and infrastructure was improved. Production expanded, forest land improvement intensified, and organizational efficiency was boosted. The company began exporting more actively.

Employee unity was fostered through sports and cultural events. By the end of the 1980s, Tamsalu EPT had strengthened its position in industrial and land improvement sectors and was ready to expand into new markets.

1990s: Transition to Market Economy, Export, and Expansion

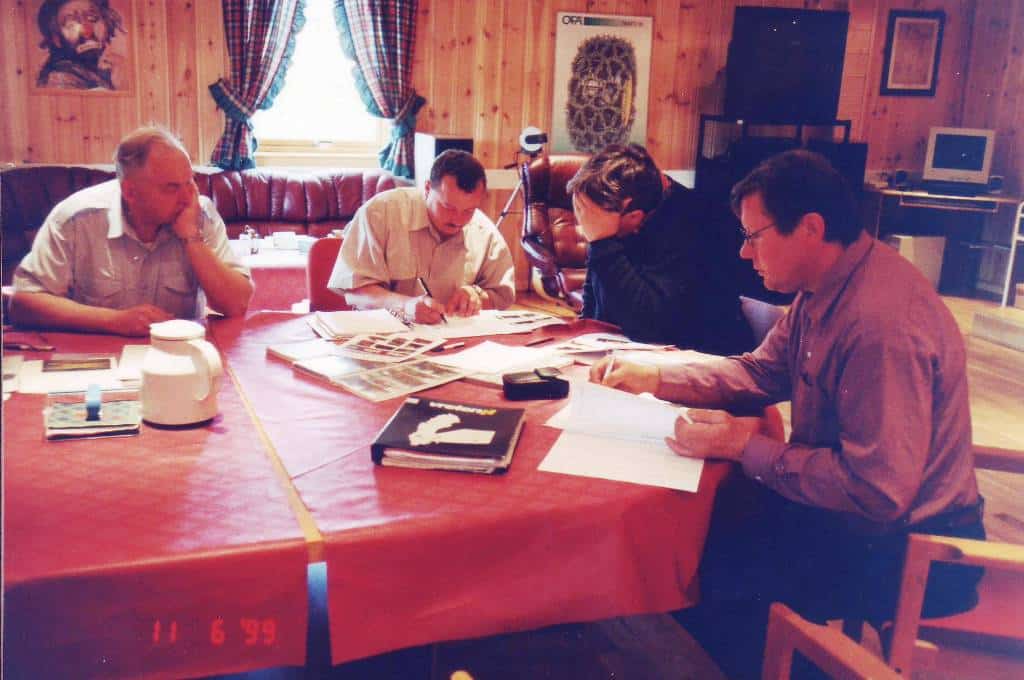

From 1991 to 2000, Tamsalu EPT underwent major restructuring due to Estonia’s re-independence and the transition to a market economy. State orders, particularly in forest drainage, disappeared, and the workforce was reduced. However, workshop production increased as the company shifted focus to partnerships with Finland, Sweden, and Norway.

In 1993, the joint-stock company RAS Tamsalu EPT was established as a step toward privatization. By 1995, employees had acquired shares in the company, helping to ensure stability.

Post-independence, production diversified significantly — new materials and technologies emerged, and the company began manufacturing snow removal equipment, tipping trailers, and buckets for loaders and excavators. What started as a small workshop evolved into a full-fledged industrial company capable of meeting both domestic and international demands.

Looking northward, Tamsalu EPT secured long-term export partners in Finland and Norway in the 1990s, and international sales picked up. At the same time, production began on specialized excavator buckets for construction and agricultural use. Today, Tamsalu’s equipment is sold not only in the Nordic countries but also across the Baltics.

By the mid-1990s, land improvement volumes decreased, but the company found success in selling forestry machinery abroad. Despite a challenging economic climate and strong competition, Tamsalu EPT adapted to the new conditions and continued to grow.

2000s: A Modern Industrial Company and International Expansion

In the 2000s, the workshop gradually transformed into a modern factory. The company gained recognition among Estonia’s fastest-growing businesses, made it into the Gazelle TOP list, and received an ISO 9001:2000 certification for production quality for three years. Production continued to grow, and the export of forestry equipment to the United States marked a major step into international markets.

Although the 2008–2009 financial crisis had an impact, Tamsalu EPT celebrated its 60th anniversary in 2010 and continued investing in factory modernization and technical upgrades, including lifting capacity improvements.

2010–2020: Transformation and Development of Manufacturing Operations

The years 2010–2020 marked a period of transformation and challenges for the company, as land improvement activities were phased out and focus shifted toward developing the manufacturing unit and workshop. In 2011, Estonia adopted the euro, and the company introduced new machines and created product catalogs to simplify the sales process. This period also saw major investments in production equipment and building renovations, including upgrades to the office and welfare facilities, improvements in ventilation systems, and enhanced working conditions.

Production volumes decreased by up to 50% due to the financial crisis preceding the COVID-19 pandemic, and the company had to adapt to smaller batches and custom orders. A shortage of skilled labor and wage pressure became key challenges. Strong client relationships and consistent participation in trade fairs like Maamess helped maintain product development and market presence.

In 2020, the company celebrated its 70th anniversary and made significant infrastructure investments in its production base – including road paving and improvements in workplace safety.

This decade can be summarized as a time of restoring business stability after the recession, with an emphasis on quality and meeting customer needs in a changing market landscape.

Key People Throughout History

The success of Tamsalu EPT has been made possible by many dedicated and exceptional individuals. Here are a few notable examples:

Aleksei Potjomkin led the company from 1950 to 1955, establishing the foundational structure and future outlook of Tamsalu EPT.

Potjomkin served as the director of Tamsalu Forest Management Unit (the predecessor of EPT) and laid the groundwork for its future development. Under his leadership, work processes and discipline improved, creating the conditions necessary for future production. He is considered one of the key architects of Tamsalu EPT’s early structure.

Sergei Kurotškin led the company from 1955 to 1986 and transformed Tamsalu EPT into a leading machine maintenance service provider in the Estonian SSR.

A legendary leader and honored engineer of the Estonian SSR, Kurotškin oversaw the development of much of Tamsalu’s industrial and living environment. A former candidate for the national volleyball team, he introduced a strong sports culture in Tamsalu and remained an active coach and athlete throughout his life. Known as a fair, demanding, and dedicated leader, he received the Tamsalu Recognition Award and left a lasting impact far beyond his formal duties.

Ants Arukuusk led Tamsalu EPT from 1986 to 2009, turning it into one of Estonia’s leading centers for land improvement and physical culture.

Under his leadership, a small sports collective evolved into a sports club that included nearly 90% of the employees and nurtured dozens of master-level athletes.

He actively contributed to the well-being of the Tamsalu community – founding a kindergarten, sports complex, residential area, and organizing employee events for decades.

Even during the complex privatization period, he maintained the company’s course and looked after the future of its employees, demonstrating extraordinary commitment and vision.

Valdo Simonlatser, CEO from 2009 to 2018, steered the company toward the metal industry, bringing land improvement operations to a close.

Simonlatser played a key role during a challenging transitional period as the company adapted to the post-Soviet system and sought its place in a new economic landscape. Under his leadership, a strong partnership was formed with the Finnish metal industry, opening doors to international markets and relocating a significant portion of production to Scandinavian countries. He was recognized as a balanced and committed leader who cared deeply about both the company’s development and employee well-being.

Aivar Maasik served as managing director from 2019 to 2024, guiding the company through a turbulent global economic period.

Under his leadership, the company weathered economic downturns and other challenging circumstances. His technical background and expertise in quality management have helped maintain high standards in production.

Today: Reliability, Innovation, Quality

Over the years, Tamsalu EPT’s product range has expanded and diversified to include excavator buckets, road maintenance machinery, forestry equipment, and agricultural implements. All our products are designed to withstand demanding working conditions and offer long service life, while providing the flexibility needed to meet the requirements of various industries.

We manufacture over thirty standard types of buckets for excavators and loaders, using world-renowned high-strength steels such as HARDOX and STRENX. These materials ensure durability and strength, enabling our buckets to withstand heavy loads and harsh conditions, which in turn helps clients reduce maintenance and operating costs.

Today, all production takes place in Lääne-Viru County, with enclosed production facilities covering nearly 4,000 square meters. Every product is manufactured from high-quality welding materials and subjected to strict quality control, ensuring compliance with industry standards and customer expectations.

Our manufacturing process is built to be flexible – allowing us to fulfill custom orders and meet the specific needs of heavy equipment distributors and end users such as farmers, foresters, and road builders.

Customer-centricity is at the heart of Tamsalu EPT’s operations. Our team works every day to thoroughly understand customer needs and deliver solutions that boost efficiency and productivity. Reliability, innovation, and quality are the core values we uphold in our daily work – values that help us maintain lasting and trusted relationships with both local and international partners.

Your Partner in Metal Industry

We take pride in our history and traditions but keep a steady eye on the future, continuing to invest in new technologies and collaborate with clients and partners internationally.

We are ready to take on new challenges and remain committed to advancing Estonia’s metal industry.

If you’re looking for a reliable partner in the metalworking industry, Tamsalu EPT is here to support you. Explore our product range here and feel free to get in touch – let’s find the solutions that fit your needs.